- Feed stone size: ≤1020mm

- Capacity: 15-750T/H

- Applicable material: Limestone, granite, marble, basalt, iron ore, river pebbles, shale, coal, pebbles, construction waste, construction waste.

- Applicable fields: Widely used in various industries of mineral crushing, mining, metallurgy, building materials, highways, railways, chemicals, construction and others.

What Are Stone Crushers for Sale Used for?

La jaw stone crusher for sale is mainly used to crush various medium and high hardness minerals and rocks, such as granite, marble, quartz stone, iron ore, limestone, etc.

Aggregate plant with two jaw crushers for sale to the Philippines

Purpose of use: large size aggregate production

Production capacity: 30-50t/h

Final configuration: APG-50G vibrating feeder + APJ-4060E jaw crusher + APJ-2510X jaw crusher + APS-1548Y4 vibrating screen

La impact crusher It is suitable for medium-hard minerals and rocks, whose hardness is between 5 and 16, such as limestone, gypsum, hard sandstone, coal, etc.

Mobile impact crusher plant to Peru

Purpose of use: stone crushing

Production capacity: 70-100tph

Final configuration: APY3-1210F mobile impact crushing plant: (APG-3896W vibrating feeder + APF-1210H European version hydraulic impact crusher + APS-1848Y4 vibrating screen)

Compared with the impact crusher, the cone crusher It has a higher crushing ratio and higher crushing efficiency, and can better meet the crushing needs of medium-hard stones, such as iron ore, non-ferrous metals, emery, bauxite, quartz sand, perlite, basalt, etc.

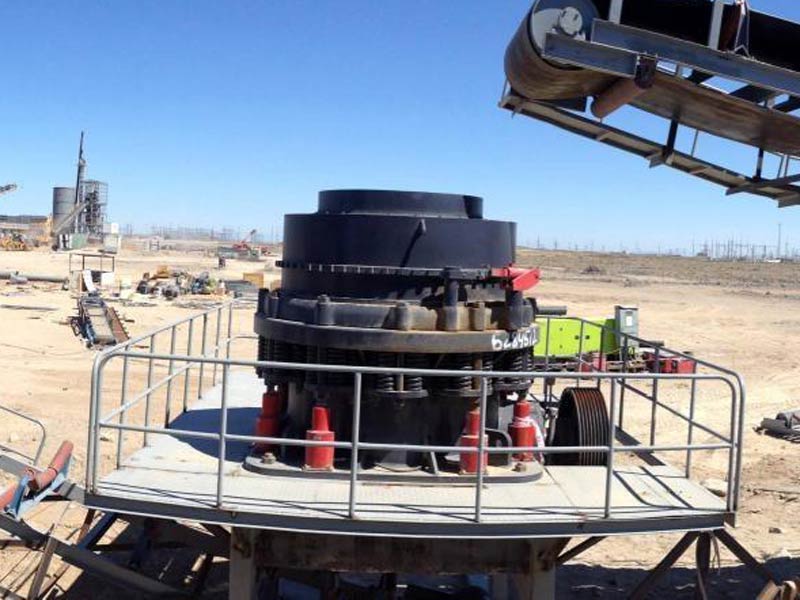

Sand plant with cone crusher in Uzbekistan

Purpose of use: make and sell sand

Production capacity: 150-200tph

Final configuration: APJ-7510E (jaw crusher) + APC-220C-M (medium crushing compound cone crusher) + APC-220C-F (fine crushing compound cone crusher)

Based on different types of stone crushers for sale and related feeders, vibrating screens, conveyors, sand washers, etc., our engineers can customize a complete crushing and sand production production line for you according to your needs. specific. If it is to be applied to a mining project, a fixed stone crushing plant design with different combinations of crushers can be used. If it is to be applied to construction projects, a mobile crushing plant Composed of mobile crushers can be used to adapt to different construction sites.

Types of Stone Crushers for Sale from AIMIX Grupo

jaw stone crusher

2. All our jaw crushers are equipped with hydraulic adjustment mechanism. The hydraulic adjustment mechanism can adjust the jaw gap according to the final product size required.

3. AIMIX jaw crushers are divided into common type APJ-E series, European type APJ-V series and fine crushing type APJ-X series. The European style jaw crusher adopts optimized product design and its output has increased by more than 30%. The fine grinder is capable of producing smaller finished particles.

APJ-E Jaw Crusher

| Model | Feeding opening (mm) | Max Feed Size(mm) | Outlet size(mm) | Capacity(t/h) | Power(kw) | Overall dimension(mm) | Weight(t) |

|---|---|---|---|---|---|---|---|

| APJ-1525E | 150 × 250 | 130 | 15-45 | 1-4 | 5.5 | × × 896 745 935 | 0.8 |

| APJ-2540E | 250 × 400 | 210 | 20-80 | 5-20 | 15 | × × 1450 1315 1296 | 2.8 |

| APJ-4060E | 400 × 600 | 340 | 40-100 | 16-60 | 30 | × × 1565 1732 1586 | 6.7 |

| APJ-5075E | 500 × 750 | 425 | 50-100 | 40-110 | 55 | × × 1890 1916 1870 | 11.7 |

| APJ-6090E | 600 × 900 | 500 | 65-180 | 80-180 | 55-75 | × × 2305 1840 2298 | 16 |

| APJ-7510E | 750 × 1060 | 630 | 80-180 | 110-320 | 90-110 | × × 2450 2472 2840 | 28 |

| APJ-8010E | 800 × 1060 | 680 | 100-200 | 140-340 | 90-110 | × × 2610 2556 2800 | 30 |

| APJ-8710E | 870 × 1060 | 720 | 170-270 | 180-360 | 90-110 | × × 2260 2556 2800 | 31.5 |

| APJ-9012E | 900 × 1200 | 750 | 95-225 | 220-450 | 110-132 | × × 3335 3182 3025 | 49 |

| APJ-1012E | 1000 × 1200 | 850 | 125-280 | 280-550 | 110-132 | × × 3435 3182 3025 | 52 |

| APJ-1215E | 1200 × 1500 | 1000 | 150-300 | 400-800 | 160-220 | × × 4200 3732 3843 | 101 |

APJ-V European Standard Jaw Crusher

| Model | Feeding opening (mm) | Max Feed Size(mm) | Outlet size(mm) | Capacity(t/h) | Power(kw) | Overall dimension(mm) | Weight(t) |

|---|---|---|---|---|---|---|---|

| APJ-80V | 510 × 800 | 420 | 40-175 | 65-220 | 75 | × × 2500 1750 1950 | 7.5 |

| APJ-100V | 760 × 1000 | 640 | 70-200 | 150-350 | 90-110 | × × 3100 1980 2490 | 20 |

| APJ-106V | 700 × 1060 | 600 | 70-200 | 150-400 | 110 | × × 3450 1900 2490 | 13.5 |

| APJ-110V | 850 × 1100 | 720 | 70-200 | 190-450 | 160 | × × 3750 2280 2880 | 25 |

| APJ-125V | 950 × 1250 | 800 | 100-250 | 290-500 | 160 | × × 4870 2850 3570 | 36.7 |

| APJ-140V | 1070 × 1400 | 900 | 125-250 | 350-550 | 200 | × × 5100 3050 3790 | 45.3 |

| APJ-145V | 1100 × 1400 | 930 | 125-275 | 400-650 | 200 | × × 5300 3150 3890 | 53.8 |

| APJ-160V | 1200 × 1600 | 1000 | 150-275 | 500-800 | 250 | × × 5500 3250 3990 | 68.6 |

APJ-X Fine Jaw Crusher

| Model | Feeding opening (mm) | Max Feed Size(mm) | Outlet size(mm) | Capacity(t/h) | Power(kw) | Overall dimension(mm) | Weight(t) |

|---|---|---|---|---|---|---|---|

| APJ-1575X | 150 × 750 | 120 | 18-48 | 8-25 | 15 | × × 1380 1658 1025 | 3.5 |

| APJ-2575X | 250 × 750 | 210 | 25-60 | 13-35 | 30 | × × 1545 1667 1330 | 5 |

| APJ-2510X | 250 × 1000 | 210 | 25-60 | 16-52 | 30-37 | × × 1530 1992 1380 | 6.5 |

| APJ-2512X | 250 × 1200 | 210 | 25-60 | 20-61 | 37-45 | × × 1900 2192 1430 | 8.8 |

| APJ-3013X | 300 × 1300 | 250 | 20-90 | 25-95 | 55-75 | × × 1750 2320 1724 | 12.6 |

stone impact crusher

2. Optimally designed crushing cavity and heavy duty rotor structure increase team production by more than 20%.

3. Impact crusher AIMIX It is available in types of two APF series cavities and three APF-V series cavities. The three-chamber impact crusher has the advantages of uniform particle size and large fine particle size ratio. The two-chamber type has greater processing capacity.

APF impact crusher

| Model | Rotor diameter × length (mm) | Maximum feed size (mm) | Feed Particle Size (Max,mm) | Capacity (t) | Power (kW) | Weight (t) | Overall dimension (mm) |

|---|---|---|---|---|---|---|---|

| APF1210 | Φ1200 × 1000 | 450 × 1060 | 350 | 100-160 | 90-110 | 17 | × × 2550 1940 2110 |

| APF1214 | Φ1200 × 1400 | 450 × 1440 | 400 | 130-200 | 132-160 | 22 | × × 2550 2340 2110 |

| APF1315 | Φ1300 × 1500 | 550 × 1530 | 450 | 180-320 | 160-200 | 29 | × × 2720 2460 2410 |

| APF1320 | Φ1300 × 2000 | 610 × 1900 | 500 | 230-400 | 200-250 | 38 | × × 2720 3060 2410 |

| APF1415 | Φ1400 × 1500 | 800 × 1530 | 600 | 280-450 | 250-315 | 40 | × × 3120 2650 2660 |

| APF1520 | Φ1500 × 2000 | 830 × 2040 | 700 | 320-550 | 315-400 | 45 | × × 3959 3564 3330 |

APF-V three-cavity impact crusher

| Model | Rotor diameter × length (mm) | Maximum feed size (mm) | Feed Particle Size (Max,mm) | Capacity (t) | Power (kW) | Weight (t) | Dimension L×W×H (mm) |

|---|---|---|---|---|---|---|---|

| APF1007V | Φ1000 × 700 | 400 × 730 | 200 | 20-50 | 45-55 | 9.5 | × × 2400 1550 2660 |

| APF1010V | Φ1000 × 1050 | 400 × 1080 | 200 | 35-80 | 55-75 | 12.2 | × × 2400 2250 2620 |

| APF1210V | Φ1250 × 1050 | 570 × 1030 | 250 | 70-120 | 90-110 | 15 | × × 2690 2338 2890 |

| APF1214V | Φ1250 × 1400 | 570 × 1430 | 250 | 90-180 | 132-160 | 18.5 | × × 2690 2688 2890 |

| APF1315V | Φ1320 × 1500 | 625 × 1530 | 350 | 150-250 | 160-200 | 19.5 | × × 3096 3273 2667 |

| APF1320V | Φ1320 × 2000 | 625 × 2030 | 350 | 160-350 | 200-280 | 28 | × × 3096 3560 3185 |

| APF1415V | Φ1400 × 1500 | 800 × 1530 | 400 | 280-350 | 250-315 | 33 | × × 3220 3473 2960 |

| APF1520V | Φ1500 × 2000 | 1315 × 2040 | 500 | 300-500 | 315-400 | 43 | × × 3890 3564 3220 |

cone crusher

2. Frequently used in secondary and tertiary crushing applications, these compact cone crushers are ideal for produce aggregates and significantly reduce rock size at high production rates.

3. The cone crusher can be converted from the finest cavity to the coarsest replacing mantle, bowl liner, adapter ring and shim bolts.

APC-Y cone crusher

| Model | Crushing cone diameter (mm) | Cavity type | Maximum feed size (mm) | Discharge port adjustment range (mm) | Capacity (t/h) | Mixing power (km) | Dimension (L×W×H) (mm) | Weight (t) |

|---|---|---|---|---|---|---|---|---|

| APC-600Y | 600 (2'ft) | B | 65 | 12-25 | 12-25 | 30 | × × 1740 1225 1940 | 5.5 |

| D | 35 | 3-13 | 5-23 | |||||

| APC-900Y | 900 (2'ft) | B | 115 | 15-50 | 50-90 | 55 | × × 1990 1640 2380 | 10.2 |

| Z | 60 | 5-20 | 20-65 | |||||

| D | 40 | 3-13 | 15-50 | |||||

| APC-1200Y | 1200 (2'ft) | B | 145 | 20-50 | 110-200 | 110 | × × 2805 2300 2980 | 25.5 |

| Z | 100 | 8-26 | 50-150 | |||||

| D | 50 | 3-15 | 18-105 | |||||

| APC-1750Y | 1750 (2'ft) | B | 215 | 25-60 | 280-480 | 160 | × × 3610 2950 4185 | 50.5 |

| Z | 185 | 10-30 | 115-320 | 51 | ||||

| D | 85 | 5-15 | 75-230 | 52 | ||||

| APC-2200Y | 2200 (2'ft) | B | 300 | 30-60 | 590-1000 | 260-280 | × × 4790 3430 5080 | 84 |

| Z | 235 | 10-30 | 200-580 | 85 | ||||

| D | 110 | 5-16 | 120-340 | 85 |

APC-C cone crusher

| Model | Crushing cone diameter(mm) | Cavity type | Maximum feed size (mm) | Output adjustment range (mm) | Capacity (t/h) | Power (kW) | Dimension L×W×H(mm) | Weight (t) |

|---|---|---|---|---|---|---|---|---|

| APC-30C | 600(2'ft) | C | 95 | 10-38 | 20-75 | 30 | × × 2195 1158 1650 | 5.3 |

| F | 72 | 6-38 | 18-60 | |||||

| APC-75C | 900(3'ft) | C | 150 | 25-38 | 59-129 | 75 | × × 2660 1640 2240 | 9.9 |

| M | 150 | 13-38 | 45-91 | |||||

| F | 85 | 9-22 | 27-90 | |||||

| APC-110C | 1000(3.3'ft) | C | 160 | 13-31 | 80-235 | 110 | × × 2760 1954 2255 | 10.8 |

| M | 115 | 10-25 | 65-150 | |||||

| F | 80 | 8-25 | 50-95 | |||||

| APC-132C | 1200(3.75'ft) | C | 180 | 13-38 | 115-260 | 132 | × × 2850 2365 2340 | 15.5 |

| M | 130 | 10-25 | 100-175 | |||||

| F | 90 | 10-19 | 80-140 | |||||

| APC-160C | 1295(4.25'ft) | C | 200 | 16-51 | 150-390 | 160 | × × 2960 2450 3155 | 23 |

| M | 150 | 13-25 | 115-210 | |||||

| F | 102 | 10-19 | 90-160 | |||||

| APC-220C | 1400(4.5'ft) | C | 215 | 19-51 | 200-420 | 220 | × × 3430 2690 3380 | 27 |

| M | 160 | 16-38 | 155-220 | |||||

| F | 115 | 13-22 | 150-230 | |||||

| APC-250C | 1650(5'ft) | C | 235 | 22-64 | 240-570 | 250 | 37.8 | |

| M | 175 | 19-38 | 215-320 | × × 3940 2954 3770 | ||||

| F | 130 | 13-25 | 180-275 | |||||

| APC-315C | 1800(5.5'ft) | C | 267 | 22-64 | 330-655 | 315 | × × 4310 3250 4530 | 44.3 |

| M | 203 | 16-25 | 230-330 | |||||

| F | 140 | 13-22 | 185-340 |

APC-D cone crusher

| Model | Cavity type | Standard type | Capacity(t/h) | Power (kW) | Weight (t) | |

|---|---|---|---|---|---|---|

| Maximum feed size(mm) | Minimum discharge opening (mm) | |||||

| APC-100D | M | 105 | 10 | 55-90 | 90 | 5.8 |

| MF | 85 | 8 | 45-80 | |||

| EF | 32 | 6 | 40-65 | |||

| APC-430D | EC | 185 | 13 | 70-200 | 132 | 12 |

| C | 145 | 13 | 66-150 | |||

| MC | 115 | 10 | 65-145 | |||

| M | 90 | 10 | 60-105 | |||

| MF | 75 | 8 | 50-90 | |||

| F | 50 | 6 | 48-80 | |||

| APC-440D | EC | 215 | 16 | 120-380 | 220 | 14.5 |

| C | 175 | 13 | 110-335 | |||

| MC | 140 | 13 | 100-320 | |||

| M | 110 | 13 | 95-280 | |||

| MF | 85 | 10 | 95-240 | |||

| F | 70 | 8 | 90-200 | |||

| APC-660D | EC | 270 | 16 | 190-510 | 315 | 26.8 |

| C | 215 | 16 | 180-500 | |||

| MC | 175 | 16 | 175-490 | |||

| M | 135 | 16 | 200-430 | |||

| MF | 115 | 13 | 190-380 | |||

| F | 90 | 13 | 195-320 | |||

APC-M cone crusher

| Model | Cavity type | Standard type | 短头型 | Capacity(t/h) | Power (kW) | Weight (t) | ||

|---|---|---|---|---|---|---|---|---|

| Maximum feed size(mm) | Minimum discharge opening (mm) | Maximum feed size(mm) | Minimum discharge opening (mm) | |||||

| APC-200M | C | 185 | 19 | 76 | 10 | 90-250 | 132-200 | 14.8 |

| M | 125 | 17 | 54 | 6 | ||||

| F | 95 | 13 | 23 | 6 | ||||

| EF | 10 | 5 | ||||||

| APC-300M | EC | 230 | 25 | 115-440 | 180-250 | 20 | ||

| C | 210 | 20 | 75 | 10 | ||||

| M | 150 | 15 | 50 | 8 | ||||

| F | 105 | 10 | 20 | 6 | ||||

| EF | 20 | 6 | ||||||

| APC-400M | EC | 295 | 30 | 140-630 | 280-355 | 32 | ||

| C | 250 | 25 | 90 | 10 | ||||

| M | 195 | 20 | 50 | 8 | ||||

| F | 110 | 14 | 40 | 6 | ||||

| EF | 30 | 6 | ||||||

| APC-500M | EC | 330 | 30 | 175-790 | 355-450 | 40 | ||

| C | 285 | 25 | 90 | 13 | ||||

| M | 200 | 20 | 55 | 10 | ||||

| F | 133 | 16 | 40 | 8 | ||||

| EF | 35 | 6 | ||||||

| APC-800M | EC | 353 | 32 | 260-1200 | 550-630 | 70 | ||

| C | 297 | 32 | 155 | 13 | ||||

| M | 267 | 25 | 92 | 10 | ||||

| F | 219 | 16 | 33 | 6 | ||||

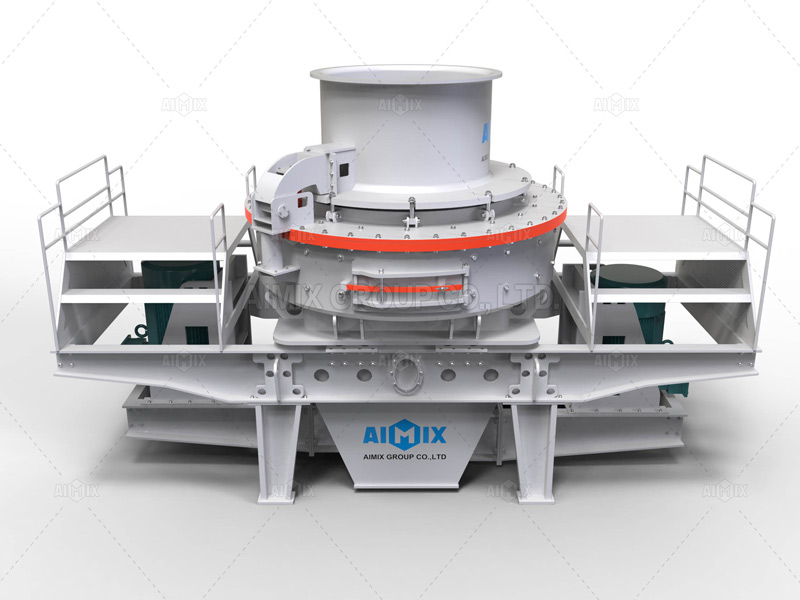

Vertical Shaft Impact Crusher

2. With its wide operating range and first-class performance, it is the most effective and reliable crusher, especially suitable for fine crushing and medium fine crushing of grinding material, fire-resistant material, cement, quartz sand and brittle material.

3. This highly effective and energy-saving crusher is also a superior and top-notch sand production equipment and can save up to 50% energy compared to traditional sand production machines.

APV Vertical Shaft Impact Crusher

| Model | APV-7611 | APV-8518 | APV-9526 | APV-1140 | |

|---|---|---|---|---|---|

| Capacity (t/h) | Full center feed | 60-90 | 100-130 | 150-190 | 225-260 |

| Surround feed and center feed | 120-180 | 200-260 | 300-380 | 450-520 | |

| Maximum Feed Size | soft material | 35 | 40 | 45 | 50 |

| Hard material | 30 | 35 | 40 | 45 | |

| Speed (r/min) | 1700-1900 | 1520-1700 | 1360-1510 | 1180-1310 | |

| Dual motor power | 110-150 | 180-220 | 260-320 | 400-440 | |

| Dimension L×W×H (mm) | × × 3700 2150 2100 | × × 4140 2280 2425 | × × 4560 2447 2778 | × × 5000 2700 3300 | |

| Weight (t) | the crushing between the stone and the impact plate | 7.8 | 10.3 | 16 | 25.6 |

| Thin oil lubrication station | Dual oil pump power | 2 × 0.37 | |||

| Security measures | Supplemental oil supply by dual oil pumps; automatic shutdown without oil return; water cooling; automatic heating at low temperature | ||||

| Fuel tank heating power | 2 | ||||

| Dimension L×W×H (mm) | × × 820 520 1270 | ||||

| The above are standard series vertical axis sand making machines | |||||

APV-X High Efficiency Vertical Shaft Impact Crusher

| Model | APV-7615X | APV-8522X | APV-9532X | APV-1145X | APV-1263X | |

|---|---|---|---|---|---|---|

| Capacity (t/h) | Full center feed | 70-140 | 120-200 | 180-280 | 250-360 | 350-480 |

| Surround feed and center feed | 150-280 | 240-380 | 350-540 | 500-640 | 500-750 | |

| Maximum Feed Size | soft material | 40 | 50 | 50 | 60 | 60 |

| Hard material | 35 | 45 | 45 | 50 | 55 | |

| Speed (r/min) | 1700-1900 | 1500-1700 | 1300-1510 | 1100-1310 | 900-1200 | |

| Dual motor power | 110-150 | 180-220 | 260-320 | 400-440 | 500-630 | |

| Dimension L×W×H (mm) | × × 4100 2330 2300 | × × 4140 2500 2700 | × × 4560 2600 2900 | × × 5100 2790 3320 | 5300X2990×3720 | |

| Weight (t) | crush between stones | 12.1 | 14.8 | 18.6 | 27.5 | 34.5 |

| Thin oil lubrication station | Dual oil pump power | 2 × 0.37 | ||||

| Security measures | Supplemental oil supply by dual oil pumps; automatic shutdown without oil return; water cooling; automatic heating at low temperature | |||||

| Fuel tank heating power | 2 | |||||

| Dimension L×W×H (mm) | × × 820 520 1270 | |||||

| The above are high efficiency sand making machines of fine crushing series with multi-channel projectile material crushing cavity. | ||||||

portable stone crusher for sale

2. AIMIX has different types of mobile stone crushers for sale, basically divided into type of wheels and caterpillar type, and can be equipped with the different types of crushers mentioned above. However, its application is not only limited to the reduction of mineral size in easy-to-work aggregates, but also in mining and recycling applications.

3. Due to their relatively small size, they are often mounted on trucks, making them very easy to move and use in various projects. A mobile crushing plant for sale can be easily obtained from AIMIX.

First Mobile Crushing Plant

| Model | APY2-57J | APY2-69J | APY2-750J | APY2-110J |

|---|---|---|---|---|

| Feeder model | APG-3090W | APG-3896W | APG-4211W | APG-4211W |

| Crusher model | APJ-5075E | APJ-6090E | APJ-7510E | APJ-110V |

| Maximum feed size (mm) | 425 | 500 | 630 | 650 |

| Silo volume (m3) | 4 | 5.3 | 7 | 7 |

| Main conveyor belt model | B650×8.5m | B800×8.5m | B1000×10m | B1000×10m |

| Side conveyor belt model (optional) | B500×4m | B500×4m | B650×5m | B650×5m |

| Generator power (kW) (optional) | 120 | 160 | 200 | 250 |

| Production capacity (t/h) | 45-100 | 60-160 | 110-320 | 250-400 |

| Weight (t) | 28 | 39 | 57 | 65 |

Secondary Mobile Crushing Plant

| Model | APY2-1010F | APY2-1210F | APY2-1214F | APY2-110C | APY2-160C | APY2-200C |

|---|---|---|---|---|---|---|

| Crusher model | APF-1010 | APF-1210 | APF-1214 | APC-110C | APC-160C | APC-200C |

| Vibrating screen model | APS-1548Y | APS-1848Y | APS-1860Y | APS-1848Y | APS-1860Y | APS-2160Y |

| Maximum feed size (mm) | 250 | 250 | 300 | 160 | 200 | 215 |

| Feeder conveyor belt model (optional) | B650 | B800 | B800 | B650 | B800 | B1000 |

| Output conveyor belt model (optional) | B500 | B650 | B650 | B500 | B650 | B650 |

| Model of conveyor belt under sieve | B650 | B800 | B800 | B650 | B800 | B1000 |

| Generator power (kW) (optional) | 160 | 200 | 250 | 240 | 280 | 320 |

| Production capacity (t/h) | 50-90 | 70-130 | 90-180 | 50-230 | 80-390 | 120-420 |

| Weight (t) | 26 | 34 | 42 | 32 | 37 | 42 |

Mobile Crushing Plant

| Model | APY4-4660S | APY4-4690S | APY4-57110S | APY4-6912S |

|---|---|---|---|---|

| Feeder model | APG-3090W | APG-3090W | APG-3090W | APG-3896W |

| Primary crusher model | APJ-4060E | APJ-4060E | APJ-5070E | APJ-6090E |

| Secondary crusher model | APC-600Y | APC-900Y | APC-110C | APF-1214 |

| Vibrating screen model | APS-1237Y | APS-1548Y | APS-1848Y | APS-1848Y |

| Return conveyor belt model | B500 | B650 | B800 | B1000 |

| Feeder conveyor belt model | B500 | B650 | B00 | B1000 |

| Model of conveyor belt under sieve | B650 | B800 | B1000 | B1200 |

| Production capacity (t/h) | 16-40 | 16-65 | 50-100 | 60-160 |

| Weight (t) | 41 | 45 | 53 | 50 |

Construction Waste Crushing Plant

| Model | APY3-1010F | APY3-1210F | APY3-1214F | APY3-1315F |

|---|---|---|---|---|

| Feeder model | APG-3090W | APG-3896W | APG-3896W | APG-4211W |

| Crusher model | APF-1010H | APF-1210H | APF-1214H | APF-1315H |

| Vibrating screen model | APS-1548Y | APS-1848Y | APS-1860Y | APS-2160Y |

| Return conveyor belt model | B650 | B650 | B800 | B1000 |

| Feeder conveyor belt model | B650 | B800 | B800 | B1000 |

| Model of conveyor belt under sieve | B800 | B800 | B1000 | B1000 |

| Production capacity (t/h) | 70-150 | 100-285 | 150-350 | 180-500 |

| Weight (t) | 41 | 45 | 53 | 60 |

How to Operate Stone Crushers Safely?

When operating a stone crusher, great care must be taken to avoid accidents and damage to the equipment. Here are some safety tips for operating a stone crusher:

Get familiar with the equipment

Get familiar with the equipment

Before operating the stone crusher, be sure to read the equipment manual carefully and familiarize yourself with the function and operation method of each component.

Wear safety equipment

Wear safety equipment

When operating a stone crusher for sale, you must wear safety glasses, gloves, safety shoes and other personal protective equipment to ensure your own safety.

Check the stone crushers for sale

Check the stone crushers for sale

Before starting the equipment, it is important to carefully inspect all parts to ensure that they are working properly.

Equipment commissioning

Equipment commissioning

Before starting the equipment, ensure that all personnel leave the vicinity of the equipment and turn off the power switch. Then start the device as instructed in the manual.

Follow operating procedures

Follow operating procedures

When operating the stone crusher, you must follow the operating procedures. Do not overload the device and do not put hands or other objects on the device.

Equipment maintenance

Equipment maintenance

After using the equipment, the equipment must be maintained. Clean and inspect equipment for damage, and repair if damaged.

Train employees

Train employees

If multiple people operate the equipment, it is necessary to ensure that all employees have received safety training and understand the operating procedures and safety precautions.

How Much Does a Stone Crusher Cost for Sale?

So, What Can AIMIX Do for You?

AIMIX is a company that specializes in the production and sale of stone crusher and is committed to providing customers with a full range of stone crusher machine services, so that customers can use it with more confidence and convenience. We can bring you: