Stone crushing plant is a special equipment for producing sand and stone for construction. The sand and gravel aggregate produced is an essential raw material for the construction of houses, bridges, roads and the production of various daily consumer goods. It is widely used in concrete mixing plants, dry powder mortar plants, asphalt plants and other projects in various urban infrastructure construction and transportation construction.

AIMIX has many years of experience in crushing plant design and production, and can provide you with cost-effective equipment. And in large crushing, fine crushing and sand making jobs, our crushing plants can show perfect results.

Types of AIMIX Stone Crushing Plant

mobile crushing plant

And mobile crushing plant is flexible and convenient. It has strong maneuverability, which can save a lot of demolition and transfer costs. It is capable of crushing stones. And move with the mining of the mining area. Therefore, the transportation cost of materials is greatly reduced.

First Mobile Crushing Plant

| Model | APY2-57J | APY2-69J | APY2-750J | APY2-110J |

|---|---|---|---|---|

| Feeder model | APG-3090W | APG-3896W | APG-4211W | APG-4211W |

| Crusher model | APJ-5075E | APJ-6090E | APJ-7510E | APJ-110V |

| Maximum feed size (mm) | 425 | 500 | 630 | 650 |

| Silo volume (m3) | 4 | 5.3 | 7 | 7 |

| Main conveyor belt model | B650×8.5m | B800×8.5m | B1000×10m | B1000×10m |

| Side conveyor belt model (optional) | B500×4m | B500×4m | B650×5m | B650×5m |

| Generator power (kW) (optional) | 120 | 160 | 200 | 250 |

| Production capacity (t/h) | 45-100 | 60-160 | 110-320 | 250-400 |

| Weight (t) | 28 | 39 | 57 | 65 |

Secondary Mobile Crushing Plant

| Model | APY2-1010F | APY2-1210F | APY2-1214F | APY2-110C | APY2-160C | APY2-200C |

|---|---|---|---|---|---|---|

| Crusher model | APF-1010 | APF-1210 | APF-1214 | APC-110C | APC-160C | APC-200C |

| Vibrating screen model | APS-1548Y | APS-1848Y | APS-1860Y | APS-1848Y | APS-1860Y | APS-2160Y |

| Maximum feed size (mm) | 250 | 250 | 300 | 160 | 200 | 215 |

| Feeder conveyor belt model (optional) | B650 | B800 | B800 | B650 | B800 | B1000 |

| Output conveyor belt model (optional) | B500 | B650 | B650 | B500 | B650 | B650 |

| Model of conveyor belt under sieve | B650 | B800 | B800 | B650 | B800 | B1000 |

| Generator power (kW) (optional) | 160 | 200 | 250 | 240 | 280 | 320 |

| Production capacity (t/h) | 50-90 | 70-130 | 90-180 | 50-230 | 80-390 | 120-420 |

| Weight (t) | 26 | 34 | 42 | 32 | 37 | 42 |

Mobile Crushing Plant

| Model | APY4-4660S | APY4-4690S | APY4-57110S | APY4-6912S |

|---|---|---|---|---|

| Feeder model | APG-3090W | APG-3090W | APG-3090W | APG-3896W |

| Primary crusher model | APJ-4060E | APJ-4060E | APJ-5070E | APJ-6090E |

| Secondary crusher model | APC-600Y | APC-900Y | APC-110C | APF-1214 |

| Vibrating screen model | APS-1237Y | APS-1548Y | APS-1848Y | APS-1848Y |

| Return conveyor belt model | B500 | B650 | B800 | B1000 |

| Feeder conveyor belt model | B500 | B650 | B00 | B1000 |

| Model of conveyor belt under sieve | B650 | B800 | B1000 | B1200 |

| Production capacity (t/h) | 16-40 | 16-65 | 50-100 | 60-160 |

| Weight (t) | 41 | 45 | 53 | 50 |

Construction Waste Crushing Plant

| Model | APY3-1010F | APY3-1210F | APY3-1214F | APY3-1315F |

|---|---|---|---|---|

| Feeder model | APG-3090W | APG-3896W | APG-3896W | APG-4211W |

| Crusher model | APF-1010H | APF-1210H | APF-1214H | APF-1315H |

| Vibrating screen model | APS-1548Y | APS-1848Y | APS-1860Y | APS-2160Y |

| Return conveyor belt model | B650 | B650 | B800 | B1000 |

| Feeder conveyor belt model | B650 | B800 | B800 | B1000 |

| Model of conveyor belt under sieve | B800 | B800 | B1000 | B1000 |

| Production capacity (t/h) | 70-150 | 100-285 | 150-350 | 180-500 |

| Weight (t) | 41 | 45 | 53 | 60 |

Stationary Stone Crushing Plant

They are widely used in mines, construction waste recycling, earth and stone works, urban construction projects, roads or construction sites. They are used to crush a variety of materials: concrete aggregates, construction materials, broken stones, quarried stones, etc.

Stone Crusher Plant Plans – Real Solutions

Regarding what equipment is used to crush and make sand of various materials and how to set up the production line, our engineers have provided some solutions for our customers.

Mobile plant solutions

Solution 1 – 70-100tph mobile limestone crushing plant

- Raw materials: mainly limestone, mixed with some crushed stone and gravel

- Production capacity: 70-100tph

- Customer demand: Customer's raw material is quarry crushed material less than 180mm, and he wants to process and crush it into four materials of 0-1/4”-1/2”-3/4”-1′ for concrete production; requirements The grain shape of the finished product is good, which meets the production demand;

- Equipment configuration: APY3-1210F three combination impact crusher mobile plant (APG-3896W vibrating feeder + APF-1210H European version hydraulic impact crusher + APS-1848Y4 vibrating screen)

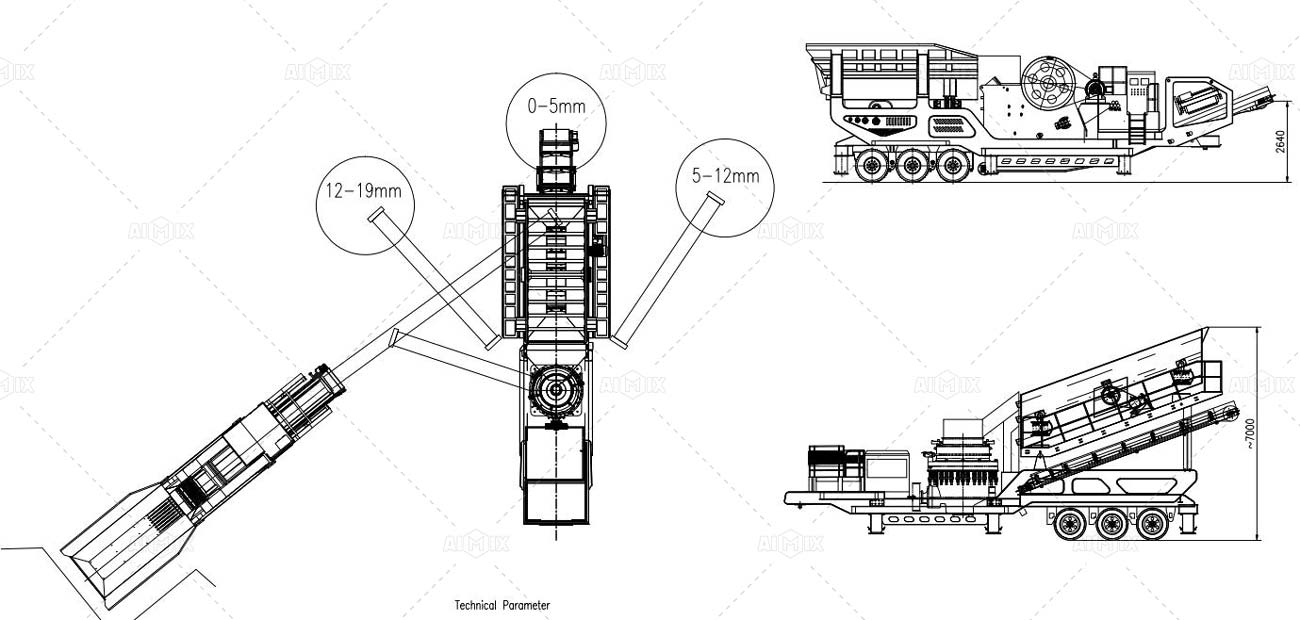

Solution 2 – mobile stone crushing plant for granite

- Raw Material: Granite

- Production capacity: 100-150T/h

- Finished product specifications: 0-5mm 5-12mm 12-19mm

- Client Needs: Client wants to continue processing large pieces of granite for local market sales and self-operated concrete mixing plants;

- Equipment configuration: APG-3896W vibrating feeder + APJ-6090E jaw crusher, APC-160C composite cone crusher + APS-1860Y3 circular vibrating screen

Stationary Crushing Plant Solutions

Solution 3 – stationary construction materials crushing plant

- Raw material: construction waste

- Production capacity: 100 t/h

- Raw material specification: below 500mm

- Final product specifications: 0-10mm, 10-20mm, 20-40mm

- Client needs: The client wants to continue processing large pieces of construction waste for sales in the local market and laying roads. The finished product is required to have a better grain shape to meet production demand.

- Equipment configuration: APG-3896W vibrating feeder + APJ-6090E jaw crusher + APF-1214V impact crusher + APS-1860Y3 circular vibrating screen

Solution 4 – fixed basalt crushing plant

- Raw material: basalt

- Production capacity: 150 t/h

- Raw material specification: below 500mm

- Final product specifications: four types of sand between 0-38 mm

- Customer needs: Used to crush basalt in the mountain and produce sand and gravel aggregates for ordinary concrete.

- Equipment configuration: APG-3895W (vibrating feeder) + APJ-6090E (jaw crusher) + APC-132C-M (medium crushing compound cone crusher) + APC-132C-F (crushing compound cone crusher) fine) + APS-2160Y4 (vibrating screen)

Crusher Models

jaw crusher

The material is delivered uniformly to the jaw crusher through the feeder. After crushing, the finished material leaves the conveyor for continuous crushing. The advantages of jaw stone crusher plant are:

- Large capacity, simple structure, easy manufacturing, reliable operation and convenient maintenance. It is used for medium and coarse crushing.

- Suitable for construction waste, large stone crushing, etc. The jaw crusher is efficient and wear-resistant. Various components are easy to adjust.

- The whole body is fully automatic, making it easy to maintain.

APJ-E Jaw Crusher

| Model | Feeding opening (mm) | Max Feed Size(mm) | Outlet size(mm) | Capacity(t/h) | Power(kw) | Overall dimension(mm) | Weight(t) |

|---|---|---|---|---|---|---|---|

| APJ-1525E | 150 × 250 | 130 | 15-45 | 1-4 | 5.5 | × × 896 745 935 | 0.8 |

| APJ-2540E | 250 × 400 | 210 | 20-80 | 5-20 | 15 | × × 1450 1315 1296 | 2.8 |

| APJ-4060E | 400 × 600 | 340 | 40-100 | 16-60 | 30 | × × 1565 1732 1586 | 6.7 |

| APJ-5075E | 500 × 750 | 425 | 50-100 | 40-110 | 55 | × × 1890 1916 1870 | 11.7 |

| APJ-6090E | 600 × 900 | 500 | 65-180 | 80-180 | 55-75 | × × 2305 1840 2298 | 16 |

| APJ-7510E | 750 × 1060 | 630 | 80-180 | 110-320 | 90-110 | × × 2450 2472 2840 | 28 |

| APJ-8010E | 800 × 1060 | 680 | 100-200 | 140-340 | 90-110 | × × 2610 2556 2800 | 30 |

| APJ-8710E | 870 × 1060 | 720 | 170-270 | 180-360 | 90-110 | × × 2260 2556 2800 | 31.5 |

| APJ-9012E | 900 × 1200 | 750 | 95-225 | 220-450 | 110-132 | × × 3335 3182 3025 | 49 |

| APJ-1012E | 1000 × 1200 | 850 | 125-280 | 280-550 | 110-132 | × × 3435 3182 3025 | 52 |

| APJ-1215E | 1200 × 1500 | 1000 | 150-300 | 400-800 | 160-220 | × × 4200 3732 3843 | 101 |

APJ-V European Standard Jaw Crusher

| Model | Feeding opening (mm) | Max Feed Size(mm) | Outlet size(mm) | Capacity(t/h) | Power(kw) | Overall dimension(mm) | Weight(t) |

|---|---|---|---|---|---|---|---|

| APJ-80V | 510 × 800 | 420 | 40-175 | 65-220 | 75 | × × 2500 1750 1950 | 7.5 |

| APJ-100V | 760 × 1000 | 640 | 70-200 | 150-350 | 90-110 | × × 3100 1980 2490 | 20 |

| APJ-106V | 700 × 1060 | 600 | 70-200 | 150-400 | 110 | × × 3450 1900 2490 | 13.5 |

| APJ-110V | 850 × 1100 | 720 | 70-200 | 190-450 | 160 | × × 3750 2280 2880 | 25 |

| APJ-125V | 950 × 1250 | 800 | 100-250 | 290-500 | 160 | × × 4870 2850 3570 | 36.7 |

| APJ-140V | 1070 × 1400 | 900 | 125-250 | 350-550 | 200 | × × 5100 3050 3790 | 45.3 |

| APJ-145V | 1100 × 1400 | 930 | 125-275 | 400-650 | 200 | × × 5300 3150 3890 | 53.8 |

| APJ-160V | 1200 × 1600 | 1000 | 150-275 | 500-800 | 250 | × × 5500 3250 3990 | 68.6 |

APJ-X Fine Jaw Crusher

| Model | Feeding opening (mm) | Max Feed Size(mm) | Outlet size(mm) | Capacity(t/h) | Power(kw) | Overall dimension(mm) | Weight(t) |

|---|---|---|---|---|---|---|---|

| APJ-1575X | 150 × 750 | 120 | 18-48 | 8-25 | 15 | × × 1380 1658 1025 | 3.5 |

| APJ-2575X | 250 × 750 | 210 | 25-60 | 13-35 | 30 | × × 1545 1667 1330 | 5 |

| APJ-2510X | 250 × 1000 | 210 | 25-60 | 16-52 | 30-37 | × × 1530 1992 1380 | 6.5 |

| APJ-2512X | 250 × 1200 | 210 | 25-60 | 20-61 | 37-45 | × × 1900 2192 1430 | 8.8 |

| APJ-3013X | 300 × 1300 | 250 | 20-90 | 25-95 | 55-75 | × × 1750 2320 1724 | 12.6 |

conical crusher

- The stone cone crusher provides higher production capacity, better product shape.

- It is easy to automate for maximum reliability and flexibility. It can create more value for users.

- It has the ability to greatly reduce sheet material. Therefore, it effectively improves the quality of the material.

- Its consumables consume less. The machine works at low cost.

APC-Y cone crusher

| Model | Crushing cone diameter (mm) | Cavity type | Maximum feed size (mm) | Discharge port adjustment range (mm) | Capacity (t/h) | Mixing power (km) | Dimension (L×W×H) (mm) | Weight (t) |

|---|---|---|---|---|---|---|---|---|

| APC-600Y | 600 (2'ft) | B | 65 | 12-25 | 12-25 | 30 | × × 1740 1225 1940 | 5.5 |

| D | 35 | 3-13 | 5-23 | |||||

| APC-900Y | 900 (2'ft) | B | 115 | 15-50 | 50-90 | 55 | × × 1990 1640 2380 | 10.2 |

| Z | 60 | 5-20 | 20-65 | |||||

| D | 40 | 3-13 | 15-50 | |||||

| APC-1200Y | 1200 (2'ft) | B | 145 | 20-50 | 110-200 | 110 | × × 2805 2300 2980 | 25.5 |

| Z | 100 | 8-26 | 50-150 | |||||

| D | 50 | 3-15 | 18-105 | |||||

| APC-1750Y | 1750 (2'ft) | B | 215 | 25-60 | 280-480 | 160 | × × 3610 2950 4185 | 50.5 |

| Z | 185 | 10-30 | 115-320 | 51 | ||||

| D | 85 | 5-15 | 75-230 | 52 | ||||

| APC-2200Y | 2200 (2'ft) | B | 300 | 30-60 | 590-1000 | 260-280 | × × 4790 3430 5080 | 84 |

| Z | 235 | 10-30 | 200-580 | 85 | ||||

| D | 110 | 5-16 | 120-340 | 85 |

APC-C cone crusher

| Model | Crushing cone diameter(mm) | Cavity type | Maximum feed size (mm) | Output adjustment range (mm) | Capacity (t/h) | Power (kW) | Dimension L×W×H(mm) | Weight (t) |

|---|---|---|---|---|---|---|---|---|

| APC-30C | 600(2'ft) | C | 95 | 10-38 | 20-75 | 30 | × × 2195 1158 1650 | 5.3 |

| F | 72 | 6-38 | 18-60 | |||||

| APC-75C | 900(3'ft) | C | 150 | 25-38 | 59-129 | 75 | × × 2660 1640 2240 | 9.9 |

| M | 150 | 13-38 | 45-91 | |||||

| F | 85 | 9-22 | 27-90 | |||||

| APC-110C | 1000(3.3'ft) | C | 160 | 13-31 | 80-235 | 110 | × × 2760 1954 2255 | 10.8 |

| M | 115 | 10-25 | 65-150 | |||||

| F | 80 | 8-25 | 50-95 | |||||

| APC-132C | 1200(3.75'ft) | C | 180 | 13-38 | 115-260 | 132 | × × 2850 2365 2340 | 15.5 |

| M | 130 | 10-25 | 100-175 | |||||

| F | 90 | 10-19 | 80-140 | |||||

| APC-160C | 1295(4.25'ft) | C | 200 | 16-51 | 150-390 | 160 | × × 2960 2450 3155 | 23 |

| M | 150 | 13-25 | 115-210 | |||||

| F | 102 | 10-19 | 90-160 | |||||

| APC-220C | 1400(4.5'ft) | C | 215 | 19-51 | 200-420 | 220 | × × 3430 2690 3380 | 27 |

| M | 160 | 16-38 | 155-220 | |||||

| F | 115 | 13-22 | 150-230 | |||||

| APC-250C | 1650(5'ft) | C | 235 | 22-64 | 240-570 | 250 | 37.8 | |

| M | 175 | 19-38 | 215-320 | × × 3940 2954 3770 | ||||

| F | 130 | 13-25 | 180-275 | |||||

| APC-315C | 1800(5.5'ft) | C | 267 | 22-64 | 330-655 | 315 | × × 4310 3250 4530 | 44.3 |

| M | 203 | 16-25 | 230-330 | |||||

| F | 140 | 13-22 | 185-340 |

APC-D cone crusher

| Model | Cavity type | Standard type | Capacity(t/h) | Power (kW) | Weight (t) | |

|---|---|---|---|---|---|---|

| Maximum feed size(mm) | Minimum discharge opening (mm) | |||||

| APC-100D | M | 105 | 10 | 55-90 | 90 | 5.8 |

| MF | 85 | 8 | 45-80 | |||

| EF | 32 | 6 | 40-65 | |||

| APC-430D | EC | 185 | 13 | 70-200 | 132 | 12 |

| C | 145 | 13 | 66-150 | |||

| MC | 115 | 10 | 65-145 | |||

| M | 90 | 10 | 60-105 | |||

| MF | 75 | 8 | 50-90 | |||

| F | 50 | 6 | 48-80 | |||

| APC-440D | EC | 215 | 16 | 120-380 | 220 | 14.5 |

| C | 175 | 13 | 110-335 | |||

| MC | 140 | 13 | 100-320 | |||

| M | 110 | 13 | 95-280 | |||

| MF | 85 | 10 | 95-240 | |||

| F | 70 | 8 | 90-200 | |||

| APC-660D | EC | 270 | 16 | 190-510 | 315 | 26.8 |

| C | 215 | 16 | 180-500 | |||

| MC | 175 | 16 | 175-490 | |||

| M | 135 | 16 | 200-430 | |||

| MF | 115 | 13 | 190-380 | |||

| F | 90 | 13 | 195-320 | |||

APC-M cone crusher

| Model | Cavity type | Standard type | 短头型 | Capacity(t/h) | Power (kW) | Weight (t) | ||

|---|---|---|---|---|---|---|---|---|

| Maximum feed size(mm) | Minimum discharge opening (mm) | Maximum feed size(mm) | Minimum discharge opening (mm) | |||||

| APC-200M | C | 185 | 19 | 76 | 10 | 90-250 | 132-200 | 14.8 |

| M | 125 | 17 | 54 | 6 | ||||

| F | 95 | 13 | 23 | 6 | ||||

| EF | 10 | 5 | ||||||

| APC-300M | EC | 230 | 25 | 115-440 | 180-250 | 20 | ||

| C | 210 | 20 | 75 | 10 | ||||

| M | 150 | 15 | 50 | 8 | ||||

| F | 105 | 10 | 20 | 6 | ||||

| EF | 20 | 6 | ||||||

| APC-400M | EC | 295 | 30 | 140-630 | 280-355 | 32 | ||

| C | 250 | 25 | 90 | 10 | ||||

| M | 195 | 20 | 50 | 8 | ||||

| F | 110 | 14 | 40 | 6 | ||||

| EF | 30 | 6 | ||||||

| APC-500M | EC | 330 | 30 | 175-790 | 355-450 | 40 | ||

| C | 285 | 25 | 90 | 13 | ||||

| M | 200 | 20 | 55 | 10 | ||||

| F | 133 | 16 | 40 | 8 | ||||

| EF | 35 | 6 | ||||||

| APC-800M | EC | 353 | 32 | 260-1200 | 550-630 | 70 | ||

| C | 297 | 32 | 155 | 13 | ||||

| M | 267 | 25 | 92 | 10 | ||||

| F | 219 | 16 | 33 | 6 | ||||

impact crusher

- The parts of the impact crusher can be easily adjusted. It is able to effectively control the discharge particle size and the particle shape is good.

- Its important components are made of new wear-resistant materials. They are shock resistant, wear resistant. Of course, they have a long lifespan.

APF impact crusher

| Model | Rotor diameter × length (mm) | Maximum feed size (mm) | Feed Particle Size (Max,mm) | Capacity (t) | Power (kW) | Weight (t) | Overall dimension (mm) |

|---|---|---|---|---|---|---|---|

| APF1210 | Φ1200 × 1000 | 450 × 1060 | 350 | 100-160 | 90-110 | 17 | × × 2550 1940 2110 |

| APF1214 | Φ1200 × 1400 | 450 × 1440 | 400 | 130-200 | 132-160 | 22 | × × 2550 2340 2110 |

| APF1315 | Φ1300 × 1500 | 550 × 1530 | 450 | 180-320 | 160-200 | 29 | × × 2720 2460 2410 |

| APF1320 | Φ1300 × 2000 | 610 × 1900 | 500 | 230-400 | 200-250 | 38 | × × 2720 3060 2410 |

| APF1415 | Φ1400 × 1500 | 800 × 1530 | 600 | 280-450 | 250-315 | 40 | × × 3120 2650 2660 |

| APF1520 | Φ1500 × 2000 | 830 × 2040 | 700 | 320-550 | 315-400 | 45 | × × 3959 3564 3330 |

APF-V three-cavity impact crusher

| Model | Rotor diameter × length (mm) | Maximum feed size (mm) | Feed Particle Size (Max,mm) | Capacity (t) | Power (kW) | Weight (t) | Dimension L×W×H (mm) |

|---|---|---|---|---|---|---|---|

| APF1007V | Φ1000 × 700 | 400 × 730 | 200 | 20-50 | 45-55 | 9.5 | × × 2400 1550 2660 |

| APF1010V | Φ1000 × 1050 | 400 × 1080 | 200 | 35-80 | 55-75 | 12.2 | × × 2400 2250 2620 |

| APF1210V | Φ1250 × 1050 | 570 × 1030 | 250 | 70-120 | 90-110 | 15 | × × 2690 2338 2890 |

| APF1214V | Φ1250 × 1400 | 570 × 1430 | 250 | 90-180 | 132-160 | 18.5 | × × 2690 2688 2890 |

| APF1315V | Φ1320 × 1500 | 625 × 1530 | 350 | 150-250 | 160-200 | 19.5 | × × 3096 3273 2667 |

| APF1320V | Φ1320 × 2000 | 625 × 2030 | 350 | 160-350 | 200-280 | 28 | × × 3096 3560 3185 |

| APF1415V | Φ1400 × 1500 | 800 × 1530 | 400 | 280-350 | 250-315 | 33 | × × 3220 3473 2960 |

| APF1520V | Φ1500 × 2000 | 1315 × 2040 | 500 | 300-500 | 315-400 | 43 | × × 3890 3564 3220 |

Some Factors Affecting the Price of Stone Crushing Plant

Production capacity

Technical level

Configuration and accessories

Brand and quality

After Sales Service

Raw material cost

Although many factors will affect the price of the crushing station, if you really need the equipment, we also recommend that you invest in a set of such equipment. because?

Why Invest in a Crushing Plant?

- 1. First of all, the most important point is that Road transport infrastructure and system in many countries are still in the development stage, and the added production problems caused by this make the crushing plant particularly important.

- 2. Secondly, crushing plants can be installed near quarries or construction sites, which minimizes transportation costs and reduces the time needed to process materials.

- 3. Thirdly, it not only saves transportation costs and time, but also reduces environmental impact, which is one of the main concerns of the mining industry.

- 4. Fourthly, stone crushing plants are versatile and can be customize to meet the specific needs of each project.

In conclusion, a stone crushing plant is essential equipment in the mining and construction industry, and its durability and reliability make it a valuable investment in any mining or construction project. By choosing the right crushing plant, companies can increase efficiency, reduce environmental impact and maximize profits. Therefore, if you have a demand for stone crushing plants, be sure to contact us to get the latest quotation.