- Capacity from 20 to 400 TPH

- Different personalized solutions

Asphalt plant is used to mix aggregates, asphalt and additives in the correct proportion to produce various types and grades of asphalt mixture. The asphalt plant for sale by AIMIX can be used to produce hot mix asphalt, warm mix asphalt, porous asphalt, dense grading asphalt, stone matrix asphalt, etc.

AIMIX can customize different types of asphalt equipment for projects, and we aim to provide customers with a complete set of solutions. Asphalt plants are mainly used in road laying and maintenance. At present, we have provided various sets of asphalt equipment solutions for customers all over the world. You can check out the completed projects below for reference. If you have a demand for asphalt plant, you can contact our engineers for detailed consultation.

AIMIX Asphalt Plants Worldwide

AIMIX is a well-known asphalt plant manufacturer in China and our equipment has been installed in many countries. At present, customers have given favorable comments to our team, and some customers even expressed that they would cooperate with AIMIX again if they had the chance.

With the various types of asphalt stations on the market, you may be dazzled and wondering how to choose. But he also believes that purchasing the right asphalt plant is the first step to the success of your project.

For AIMIX, we provide you customized asphalt plant solutions. At the same time, you can also continue to view the following content to learn the specific types and features of the asphalt stations we offer.

Types of Asphalt Plant for Sale

- Years of experience in design and production have made AIMIX Group a leading brand of asphalt plants in China. We have opted for innovation and optimization of equipment to improve the performance of asphalt plants.

- In addition, AIMIX has also optimized the model name of asphalt station, “A” means AIMIX, “L” means asphalt plant in Chinese, “T” means the expression of drying drum in continuous asphalt plant in Chinese, and “Q” means mandatory in Chinese, “Y” represents movable type in Chinese, and “J” represents simple type in Chinese.

- Once you know the AIMIX naming rules, you can better understand the model and configuration of our asphalt plant. You can see the content below and leave us a message to check the price.

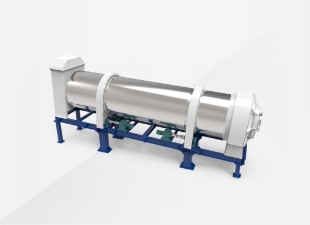

ALT CONTINUOUS ASPHALT PLANT

BENEFITS

Continuous asphalt plants are suitable for scenarios that require high performance, continuous supply and high-quality asphalt mixture, such as urban road repairs, airport and port projects, construction of large-scale industrial areas, etc.

FEATURES

They are capable of continuous production, which can improve construction efficiency and meet the needs of large-scale road construction projects. If your construction project has a short cycle or you need to produce a large amount of asphalt mixture in a short period of time, then asphalt drum equipment is a good choice for you.

APPLICATIONS

Furthermore, the biggest advantage of continuous asphalt mixing plant is its low price, and a small amount of capital can be invested in the initial stage to get a quick return.

REFERENCES

The models of AIMIX continuous asphalt plant are ALT20, ALT40, ALT60, ALT80, ALT100.

DISCONTINUOUS ASPHALT PLANT FOR RENT

BENEFITS

Compared with continuous asphalt plants, discontinuous asphalt plants have advantages in terms of production capacity and stability, and can meet the quality and performance requirements of roads.

FEATURES

It is generally suitable for large-scale road construction projects and scenarios that require high-volume, high-quality asphalt mixture, such as urban highways and arterial roads, large bridges, tunnels, parking lots, etc., road construction. large-scale industrial park, etc.

APPLICATIONS

Fixed intermittent asphalt plant generally requires higher investment and larger footprint, which is suitable for continuous and long-term road construction needs.

REFERENCES

The models of AIMIX intermittent asphalt plant are ALQ40, ALQ60, ALQ80, ALQ100, ALQ120, ALQ160, ALQ180, ALQ200, ALQ240, ALQ320, ALQ400.

ALYQ AND ALYJ MOBILE ASPHALT PLANT

BENEFITS

In addition, the mobile version of the asphalt plant is also a hot-selling product of AIMIX. The mobile asphalt plant provides a convenient asphalt production solution to help improve construction efficiency and meet project asphalt supply needs.

FEATURES

Mobile asphalt plants are suitable for engineering projects that require temporality, flexibility and mobility.

APPLICATIONS

They can adapt to the needs of various scenarios, such as temporary engineering projects, remote areas or mobile construction sites, urban construction and road renovation, as well as short-term and small-scale engineering projects.

REFERENCES

AIMIX's ALYQ series mobile asphalt plant models are ALYQ60, ALYQ80, ALYQ100, ALYQ120 and ALYQ160. The ALYJ series single asphalt plant models are ALYJ10, ALYJ20, ALYJ30, ALYJ40, ALYJ60 and ALYJ80.

AIMIX Technical Specifications Asphalt Plants for Sale

AIMIX is a well-known asphalt plant manufacturer in China and our equipment has been installed in many countries. At present, customers have given favorable comments to our team, and some customers even expressed that they would cooperate with AIMIX again if they had the chance.

ALT continuous plant

| Models | ALT20 | ALT40 | ALT60 | ALT80 | ALT100 |

|---|---|---|---|---|---|

| Capacity | 20 t/h | 45 t/h | 60 t/h | 80 t/h | 100 t/h |

| The ability to | 40kw | 75kw | 120kw | 165kw | 200kw |

| Cold Aggregate Hoppers | 3.5m³×1 | 4m³×4 | 4m³×4 | 6.5m³×4 | 6.5m³×4 |

| Finished Product Hopper | 3t | 3t | 7t | 7t | 9t |

| Asphalt Temperature | 120-180 ℃ | ||||

| Fuel consumption | 13-15kg/t | ||||

| Asphalt Tank | 10 t | 20 t | 30 t | 30 t | 35 t |

| Control room | 2.2m | 2.2m | 3m | 3m | 3.5m |

| Option | Bag dust filter | ||||

ALQ discontinuous plant

| Model | ALQ40 | ALQ60 | ALQ80 | ALQ100 | ALQ120 | ALQ160 | ALQ200 | ALQ240 | ALQ320 |

|---|---|---|---|---|---|---|---|---|---|

| Capacity | 40 t/h | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 160 t/h | 200 t/h | 240 t/h | 320 t/h |

| Cold Aggregate Hoppers | 4×4.5m³ | 4×6.5m³ | 4×7.5m³ | 4×7.5m³ | 4×7.5m³ | 5×12m³ | 5×12m³ | 5×12m³ | 6×15m³ |

| Dryer Size | φ1.2m×5.2m | φ1.5m×6m | φ1.5m×6.7m | φ1.65m×7m | φ1.8m×8m | φ2.2m×9m | φ2.6m×9m | φ2.6m×9.5m | φ2.8m×10.2m |

| Fuel consumption | 70-300kg / h | 100-400kg / h | 120-600kg / h | 150-1000kg / h | 150-1000kg / h | 150-1400kg / h | 180-1800kg / h | 180-1800kg / h | 260-2500kg / h |

| Vibrating Screen (Layer) | 4 layers | 4 layers | 4 layers | 4 layers | 4 layers | 5 layers | 5 layers | 5 layers | 6 layers |

| Mixer Capacity | 500kg | 800kg | 1000kg | 1250kg | 1500kg | 2000kg | 2500kg | 3000kg | 4000kg |

| Cycle Time | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s |

| Filter Area | 230m² | 300m² | 420m² | 480m² | 550m² | 650m² | 700m² | 1050m² | 1350m² |

| Asphalt Temperature | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ |

| Total Power | 170kw | 200kw | 300kw | 350kw | 380kw | 490kw | 550kw | 670kw | 865kw |

ALYQ mobile plant

| Model | ALYQ60 | ALYQ80 | ALYQ100 | ALYQ120 | ALYQ160 | |

|---|---|---|---|---|---|---|

| Capacity | t / h | 60 | 80 | 100 | 120 | 160 |

| Mixer capacity | kg | 800 | 1200 | 1300 | 1700 | 2200 |

| Mixing cycle | s | 45 | 45 | 45 | 45 | 45 |

| Total power | Gasoline(kW) | 54 | 63.5 | 104.5 | 125 | 157.5 |

| Coal(kW) | 75 | 86.5 | 127.5 | 169 | 205 | |

| filter area | m2 | 370 | 420 | 480 | 510 | 620 |

ALYJ simple plant

| Model | ALYJ10 | ALYJ15 | ALYJ20 | ALYJ30 | ALYJ40 | ALYJ60 | ALYJ80 | |

|---|---|---|---|---|---|---|---|---|

| Capacity | 10 t/h | 15 t/h | 20 t/h | 30 t/h | 40 t/h | 60 t/h | 80 t/h | |

| The ability to | Petrol | 48kw | 59kw | 68kw | 106kw | 132kw | 146kw | 186kw |

| Burning coal | 67kw | 78kw | 91kw | 129kw | 170kw | 192kw | 262kw | |

| Cold Aggregate Hoppers | 3m³×3 | 3m³×3 | 3m³×3 | 5m³×3 | 5m³×3 | 5m³×3 | 5m³×4 | |

| Finished Product Hopper | 2t | 5t | 5t | 9t | 9t | 9t | 20 t | |

| Asphalt Temperature | 120-180 ℃ | |||||||

| Fuel consumption | Petrol | 5-7.5kg/t | ||||||

| Burning coal | 13-15kg/t | |||||||

| Option | Water dust filter, Bag dust filter, Control room, Asphalt heat tank, Mineral flour tank | |||||||

Asphalt Plant For Sale What is it for?

At the beginning of the article, the editor has mentioned that the asphalt plant can produce hot mix asphalt, hot mix asphalt, porous asphalt, dense grading asphalt, stone matrix asphalt, etc. Although to the uninitiated, they all look more or less the same. , in reality several asphalt mixtures are used in different situations.

Technical Benefits of Asphalt Plant for Sale

What Does the Asphalt Plant Consist of?

The asphalt plant for sale has a simple structure. The components of asphalt mixing plant include cold aggregate supply system, drum dryer, dust collector, hot aggregate elevator, vibrating screen, mixer, powder supply system, asphalt supply, etc. Each of these different components has a role to play in production. the right asphalt mix for your project.

Cold Aggregate Silos

Drying Drum

Mixing Tower

Hot Aggregate Elevator

Working principle

The working process of asphalt mixing equipment is the combination of aggregate mixing, mineral powder mixing and asphalt mixing. You can find more details below.

AGGREGATE TRANSPORTATION

The cold aggregate supply system is for storing all kinds of raw materials. First, send the broken stones to the drying system through the inclined feeding conveyor belt, and after drying and heating. The hot aggregates will be sent to the screening system through the elevator. And in the vibrating screen, according to the diameter of the grains, different aggregates will enter the hot aggregate storage container, and then send the aggregates to the aggregate weighing system, after weighing, send them to the mixing cylinder. This is the process of transporting aggregates;

MINERAL POWDER TRANSPORTATION

During the transportation of aggregates, there is a drying process, and this process will produce some dusts, so these dusts will be collected by the dust collection system. And then they will enter the recycling powder warehouse. At the same time, new mineral powder will be sent to the powder silos, so mix them and send them to the mineral powder weighing system. After weighing, discharge the mineral powder into the mixing cylinder. And this is the process of transporting mineral dust;

ASPHALT TRANSPORTATION

Pour the asphalt into the asphalt tank with the asphalt pump, by the way, the asphalt tank plays an important role in keeping warm and heating. And then, send the asphalt to asphalt weighing system and after weighing, discharge the provided asphalt into the mixing cylinder. This is the process of transporting asphalt.

MIXTURE OF MATERIALS

After the above processes are finished, start mixing them in the mixing cylinder according to the designated time. And after finishing mixing, discharge the asphalt mixture into the finished product storage container. Finally, send the asphalt mixture to the construction site by the heated fuel tanker truck.

During the production of asphalt mixture, whether it is the transportation of cold aggregates or the transportation of mineral dust and other materials, some dust will be generated, so how to deal with this dust?

Environmental Management Measures for Asphalt Plants

Our AIMIX engineers have equipped different dust removal methods according to the dust generated by different parts of the asphalt plant for sale:

Bag Dust Collector

Aggregate Silos with Dust Cover

- The cold aggregate metering system will be equipped with a dust cover to reduce dust generated by the loader when loading materials.

- Plate chain conveyor adopts shaft end seal, no dust leakage.

- AIMIX asphalt plant for sale adopts multi-stage dust removal system, which can recycle dust according to particle size, minimize dust leakage and improve raw material utilization. In addition, you can also choose a high-pressure pulse bag filter for more complete dust removal and higher efficiency.

How Can We Serve Clients About

Asphalt Plant?

AIMIX Group has earned industry recognition with considerate service while providing customers with high-quality asphalt plants. Now AIMIX has a professional service team, always ready to provide users with quality services to meet their needs. Until now, we have employed more than 30 engineers and 20 after-sales service professionals in AIMIX.

- Free industrial consultations, recommending equipment configuration schemes and site planning and construction

- After equipment installation and commissioning, free technical training and support to on-site operation and maintenance personnel, to achieve independent operation

- Monitoring service, quality inspections and occasional user visits and maintenance work during the use of the asphalt plant.

- Supply of accessories for zero profit equipment

- Transfer and upgrade of free guide equipment

Find a Better Price for Asphalt Plant for Sale

When mentioning the price, some customers would like to select the asphalt mixing plant for sale with a lower price. In their eyes, the low price of the asphalt batching plant will reduce the cost of construction projects. However, most of them will regret selecting the cheap one after using the plant for a year or less. Getting a cheap plant seems to save you losses in a short time. However, you will pay a lot to keep it for a long time. We suggest customers choose the plant with reasonable price.

Of course, some of the customers favor the high price of asphalt batch mixing plant. Because they think they will get the best as long as they pay a lot. That's not the truth. If you are not a professional engineer, you will not have an accurate judgment based solely on the appearance of the plant. As a reliable asphalt plant manufacturer and supplier, we recommend customers to purchase the plant from a reliable company.

| ALT Series Continuous Drum Asphalt Plant | 60,000-250,000 |

| ALQ Series Fixed Intermittent Asphalt Plant | 220,000-1220,000 |

| ALYQ Series Mobile Intermittent Asphalt Plant | 270,000-600,000 |

| ALYJ series mobile asphalt plant | 50,000-200,000 |

Some factors to consider when purchasing an asphalt plant:

The working process of asphalt mixing equipment is the combination of aggregate mixing, mineral powder mixing and asphalt mixing. You can find more details below.

Capacity requirements:

First of all, it is necessary to determine the required asphalt production and select the appropriate asphalt station capacity according to the scale and demand of the project.

Product quality:

When purchasing an asphalt plant, it is necessary to consider the production technology and quality control of the equipment to ensure the production of asphalt products that meet the standards.

Environmental protection requirements:

Consider the environmental regulations and environmental requirements of the project, and select asphalt plants that meet the emission standards and environmental protection requirements.

Equipment Reliability:

Choose experienced and reputable suppliers and make sure they provide reliable equipment and technical support.

rentabilidad:

Consider the asphalt plant price, operation cost and maintenance cost to make a comprehensive economic evaluation.

Adaptability and flexibility:

Consider the flexibility and adaptability of the asphalt plant to meet the requirements of different engineering projects.

High Quality Manufacturer Helps You

to be successful

AIMIX Group is one of the renowned companies in China. It is established in 2003, which always concentrates on manufacturing and supplying construction machines. As a professional manufacturer and supplier, we have our own engineers, salesmen and technicians. Meanwhile, we strive to improve technology and decrease sales links.

In this way, customers will get affordable plants from our company. We are confident that we have the most reasonable asphalt mixing plant price.

And we have exported the machines to more than 80 countries. Most customers highly value our equipment and service. Whenever you need an asphalt plant for sale, AIMIX Grupo is your first choice.