Self-loading concrete mixer is a new generation concrete production and transportation tool independently developed by AIMIX. It is mainly used to produce medium to high quality concrete in various construction projects and to improve production efficiency.

The biggest difference between self-loading concrete mixer and normal concrete mixer is that it is equipped with a driving chassis, automatic feeding bucket and water tank.

At the same time, due to its small size, multiple functions and simple operation, customers use it in various scenarios. Let me explain this to you.

Wide Applications of Self-Loading Concrete Mixer

Self-loading concrete mixer is a special vehicle that is specially used for mixing, transporting and unloading concrete. They play an important role in construction engineering and infrastructure construction.

- 1. Construction sites: The self-concrete mixers They are often used to deliver fresh concrete to construction sites. They load concrete at or near a concrete mixing plant at the jobsite and transport it to where it is needed to pour floors, walls, columns and other structures.

- 2. Road construction- In road construction projects, self-loading concrete mixers are used to pour pavements, curbs and other road structures. They can quickly send concrete to different construction areas, ensuring the quality and durability of the road.

- 3. Bridge construction- Self-loading concrete mixer plays a key role in bridge construction, pouring concrete for pillars, supports and deck structures. Since bridges are often located in remote or high-altitude areas, the capacity of self-loading concrete trucks can ensure the timeliness and quality of concrete supply.

- 4. tunnel engineering: In tunnel construction, low-profile mixer trucks are used to spray concrete on the walls and ceiling of the tunnel to increase the structural strength and durability of the tunnel.

- 5. Infrastructure engineering: self-loading mixer are used in various infrastructure projects, including water conservation projects, drainage systems, water treatment facilities and wastewater treatment plants. They introduce concrete into swimming pools, pipes and other infrastructure structures.

- 6. Commercial and residential construction- In addition to large construction projects, self-loading concrete mixer trucks are also used in commercial and residential construction to pour stairs, steps, pavers, patios and other landscaping elements.

The application of self-loading concrete mixer is very broad and includes, among others, the above scenarios. At AIMIX Group, we have exported many sets of automatic loading equipment to foreign countries and received unanimous praise from customers.

Uses of Self-Loading Concrete Mixers at Customer Sites

AS-3.5 in Indonesia

Use: small construction projects, construction of residential and low-rise buildings.

Project overview: The AS-3.5 self-loading vehicle has the advantage of being able to travel on bad roads. The road in the area where the client's project is located is full of mud and the construction environment is not very good. After using it, the customer gave us feedback that the self-loading concrete mixer works very well and will not be affected by the environment.

AS-4.0 in Myanmar

Use: factory construction

Project general description: This customer from Myanmar used our self-loading concrete mixer to complete the construction of their plant, which included foundation and floor pouring, wall and column pouring, construction of foundation and equipment platforms, underground pipes and drainage systems, external roads and parking fields, etc.

AS-4.0 and stationary concrete pump in Uzbekistan

Use: production of precast concrete slabs

Project general description: The mixing drum of the AIMIX self-loading mixer can rotate 270° and can be used in combination with the stationary concrete pump to separate the concrete production site from the precast slab processing site. Use the trailer pump to connect the two sites and the self-loading truck will not circulate back and forth in the precast panel processing site, which will affect your production quality.

AS-3.5 and AS-4.0 are the two most popular among the different models of self-loading concrete mixers from the AIMIX Group. At the same time, we also offer other models for customers to choose: AS-1.8, AS-2.6, AS-5.5 and AS-6.5. So how do you choose the one that best suits your project among the many models available?

How to Choose a Suitable Model for Your Project?

Choosing the right self-loading concrete mixer model is very important, as different projects and needs may require concrete mixers of different specifications and capacities. Therefore, you should thoroughly consider several factors before purchasing to ensure that your equipment can meet your requirements. Below are some key considerations.

Capacity

One of the first things to consider when purchasing a self-loading mixer truck is the drum capacity. This will determine the amount of concrete or other material the truck can hold and transport at one time. Be sure to choose a capacity that is appropriate for your project needs.

In the above content, you can learn that the models of self-loading concrete mixers provided by AIMIX are AS-1.8, AS-2.6, AS-3.5, AS-4.0, AS-5.5, AS-6.5, and the numbers on these models represent mixing drum capacity is 1,8m3, 2,6m3, 3,5m3, 4,0m3, 5,5m3, 6,5m3.

At the same time, each self-loading concrete mixer can produce 4 barrels of concrete per hour, so according to the capacity and production batches, each type of the equipment can produce concrete per hour about 7,2m3, 10,4m3, 14m3, 16m3, 22m3, 26m3.

| Models | AS-1.2 | AS-1.8 | AS-2.6 | AS-3.5 | AS-4.0 | AS-5.5 | AS-6.5 |

|---|---|---|---|---|---|---|---|

| Mixing tank capacity | 1.2 m³ | 1.8 m³ | 2.6 m³ | 3.5 m³ | 4.0 m³ | 5.5 m³ | 6.5 m³ |

| Engine power | 55 kW | 78 kW | 78 kW | 91 kW | 91 kW | 92 kW | 92 kW |

| Water tank | 400L | 400L | 500L | 620L | 920L | 840L | 1465L |

| Total weight | 5000 Kg | 6100 Kg | 7100 Kg | 7900 Kg | 9200 Kg | 11500 Kg | 12520kg |

| L*W*H(mm) | 6400x2550x3300 | × × 7300 2650 3750 | × × 7860 2750 4100 | × × 7830 2680 4170 | × × 7640 2870 4750 | × × 8450 3100 4580 | 8450x3050x4830 |

Construction project type

Different types of construction and infrastructure projects may require different types of self-loading concrete mixers. For example, large projects may require high-capacity trucks, while smaller projects may use small self-loading concrete trucks.

Manufacturer Strength and Service

Finally, it is also necessary Consider the strength and service of the mixer manufacturer. The quality of concrete mixers produced by powerful manufacturers is more guaranteed. And reliable manufacturers can provide you with better services, such as operational training, regular inspection and maintenance, delivery of wearing parts, etc.

Construction site conditions

Consider the special conditions of the construction site, such as the width of the road, the construction space, the difficulty of loading and unloading concrete, etc. Make sure the selected self-concrete mixer model is suitable for these conditions.

Maintenance and reliability

Consider the maintenance requirements and reliability of the self-loading concrete mixer. Choose a model with high reliability and easy maintenance to reduce downtime and repair costs.

When choosing a self-loading concrete mixer model, it is best to consult a professional construction engineering consultant or concrete supplier who can provide you with useful advice depending on the specific needs and conditions of the project. Additionally, it is also possible to compare the specifications and performance of different brands and models to find the best concrete forwarder truck price for the project.

Get a Self-Loading Concrete Mixer at an Affordable Price

The prices of self-loading concrete mixer machines are diverse among the different manufacturers on the market. Many customers must be eager to choose the ideal concrete mixer at the best price. However, Self loading concrete mixer price is affected by different factors such as size, capacity, main components, raw material, shipping cost, etc.

Well, AIMIX can offer the best self-loading concrete mixer price to customers because compared with other self-loading concrete mixer manufacturing companies, we have our own factory in China. Therefore, our prices are more competitive in the market. In AIMIX Group, The price range for AS-1.2-AS-6.5 is 12000 USD to 58000 USD.

Of course, as you can see, this is just a price range, because no matter what equipment, its price fluctuates greatly with market changes. If you need equipment recommendation and quote, you can leave a message on the website and we will reply to you as soon as possible. Another reason why self-loading concrete mixer trucks AIMIX have received good reviews from customers is that our equipment has multiple advantages, you can refer to the content below to know more.

Some Advantages of Self-Loading Concrete Mixer for Sale

Self-loading concrete mixers have been gaining popularity lately due to their versatility and convenience. And they offer many advantages that make them a valuable asset for any construction project. If you want to improve the efficiency and productivity of your construction projects, consider using a self-loading concrete mixer from AIMIX.

Increased efficiency

One of the essential advantages of using a self-propelled self-loading concrete mixer is greater efficiency. These mixers can load and mix concrete independently, eliminating the need for additional equipment or labor.

Esto reduces the time and cost associated with transporting and mixing concrete, allowing for more efficient use of resources and greater productivity.

Versatility

These concrete mixers are very versatile and capable of handling various construction projects. They can be Use for small scale projects, such as home renovations, or larger projects, such as road construction.

They can also be used to mix and transport various materials, including concrete, sand and gravel.

Easy to operate

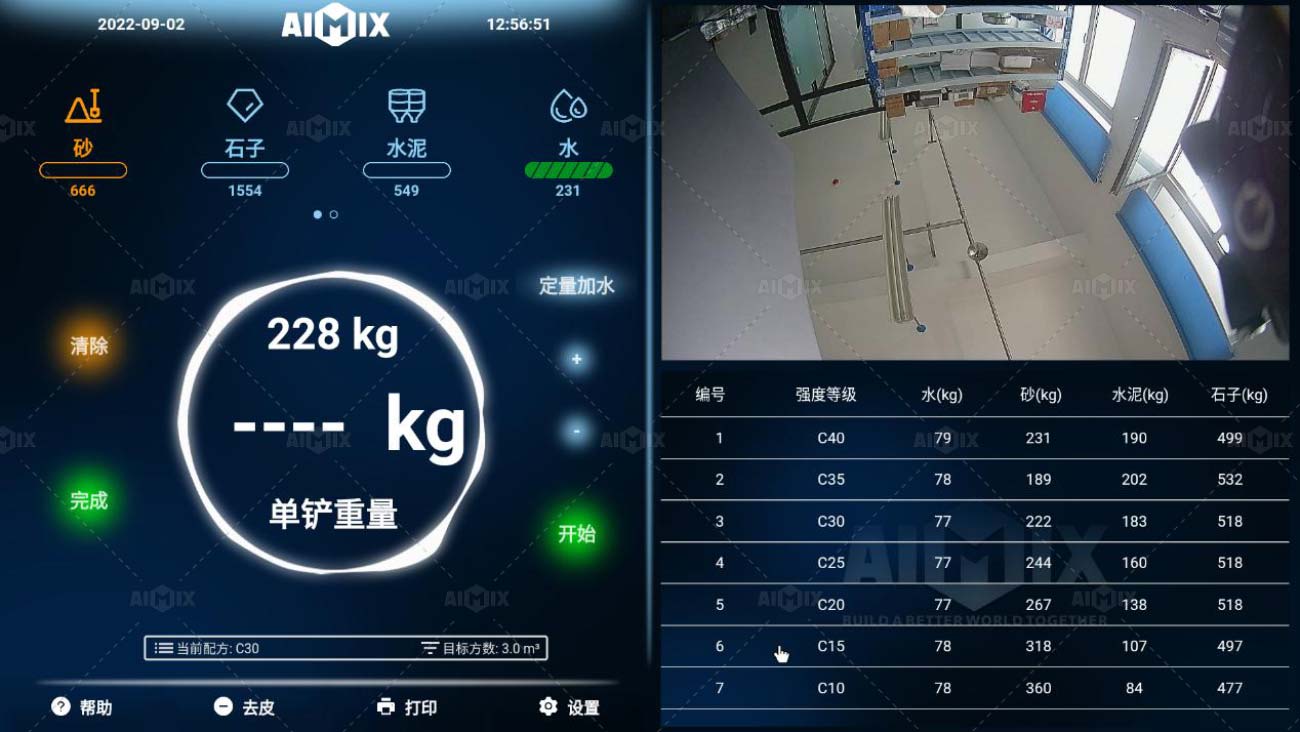

Plus, they are easy to operate, even for those with little or no construction experience. These concrete mixers are Equipped with easy-to-use controls, such as touch screen operation and smart electronic weighing, and can be operated with minimal training. This eliminates the risk of accidents and ensures projects are completed efficiently and safely.

Reduced labor costs

Using a self-loading concrete mixer can significantly reduce labor costs associated with traditional concrete mixing methods. These mixers are designed to be operated by a single person and can replace three mixer people, one forklift driver, one tanker driver and one unloading staff. This minimizes costs and makes projects more affordable for small-scale construction companies.

Improved quality control

They provide better quality control than traditional concrete mixing methods. These self-loading concrete mixers feature advanced technology that ensures a consistent mix and a high-quality finished product. This reduces the risk of errors and inconsistencies, resulting in a finished product that meets or exceeds industry standards.

The self-loading concrete mixers provided by AIMIX can provide customers with multiple advantages to improve production efficiency and save production costs. We have high-quality equipment and services to help customers receive the equipment and put it into use as soon as possible.

AIMIX Services for Customers Purchasing Self-Loading Concrete Mixers

- Consultation. After contacting us through the website or other channels (such as social media), tell us the details of your project and our account manager will help you choose the right model.

- Equipment recommendation. Subsequently, our mechanical engineer will also participate, review your project information, judge what type of equipment is most suitable for your project, and then determine the model you need.

- Provides prices. After confirming the self-loading concrete mixer model, our account manager will send you detailed quotation and equipment information. At this stage you will be able to negotiate with our account manager the configuration and price of more equipment.

- Signing the contract. After the negotiation between the two parties is completed, we will sign a purchase contract with you to protect your rights and interests.

- Equipment production. After this, we will organize the factory for production; Of course, if there is stock in the factory, you will receive your equipment soon. Otherwise, we will speed up the production and provide you with feedback on the production progress during the process. We will also carry out a test of the self-loading concrete mixer before delivery. After all, self-loading concrete mixers are very popular equipment in our AIMIX.

- Shipment. After production is completed, our shipping department will arrange shipment of the equipment and provide you with photos, videos and shipping lists.

- Installation and training. When the equipment arrives at your construction site, you can choose to guide the installation online or offline. Of course, if you have your own installation team, this will also save you some expenses. In addition, we are also responsible for checking and debugging the machine for you and training the self-loading concrete mixer operator.

How Does a Self-Loading Concrete Mixer Work?

Since the introduction of concrete in construction, various methods have been used to make concrete from cement, sand, gravel and water. The traditional method of mixing concrete is to do it by hand. This is the oldest method of concrete manufacturing and is still used in many developing and developed countries for the manufacture of concrete in small batches.

The increase in the size of construction projects has forced the replacement of manual mixing with mechanical mixing. These machines usually consist of huge rotating drums and are known as concrete mixers. They are known for their fast, efficient and bulk concrete production.

The operation of the auto concrete mixer can be explained as follows:

Loading of raw materials

Initially, raw materials are loaded onto a shovel. This shovel is self-articulating and hydraulically controlled. The operator uses a joystick to control this paddle and insert it into the drum. This is the feature that sets this machine apart from the rest of the others.

Mixing concrete materials

In the self-loading concrete mixer, the function of the drum is to mix the raw materials homogeneously. A continuous supply of water ensures that the machine operates normally and that the water level is maintained in the concrete. These drums are usually equipped with spiral blades. The drums are designed to rotate at high speed. For mixing, the drum rotation is fixed in one direction. During mixing, the spiral blade pushes the concrete materials deep into the drum. This high speed rotation ensures a homogeneous mixture of materials in the concrete.

Collection of mixed concrete materials

Once the concrete has been mixed, collecting the mixed material is the next step. This can be done in two ways. One way is by changing the direction of rotation of the spiral blades installed inside the drum. The change in direction will cause the concrete to come out of the drum. Another method is to tilt the drum. In this method, the drum is lifted from the back with the use of hydraulic pumps. This pushes the concrete out of the drum and into the collection container.

Some Self-Loading Concrete Mixer Maintenance Tips

Periodic Inspection

- Periodic inspection of the self-loading concrete mixer ensures operational efficiency. Inspection helps to identify defects at the initial stage and thus prevents future catastrophes.

- Necessary inspections include visual, mechanical, structural and electrical evaluations. They help evaluate the need for adjustment, maintenance, monitoring and/or replacement.

- Mechanical upgrades increase the reliability of the self-loading mixer by decreasing the chance of an unexpected breakdown. It also ensures durability and longevity.

Pressure wash

- It is often considered a challenge to clean the self-concrete mixer. But it will not be if it is cleaned with the help of a pressure washer.

- It will clean any dust that has accumulated on its exterior and the water will help keep the self-loading concrete mixer looking shiny and clean as if it were new.

- However, the pressure washer may seem expensive at first, but it can substantially reduce your maintenance cost.

Interior cleaning

- The interior cleaning of self-loading concrete mixers is as important as the exterior.

- A bag can be kept inside the cabin in which garbage can be collected instead of throwing empty bottles or wrappers on the floor.

- The vacuum cleaner is another best option that can be used every few months. It will remove any dirt or dust from the cabin and clean it.

Experience drivers

- The experience and skill of drivers have a great impact on the operating expenses of self-concrete mixers.

- Train self-loading concrete mixer drivers on basic maintenance and troubleshooting procedures, and how to properly operate the vehicle to reduce the risk of wear and damage.

Conclusion

Self-loading concrete mixer has large production capacity and a wide range of application fields. If you are interested or need this product, you can contact us as soon as possible to get the most cost-effective equipment. It will bring you more business opportunities and benefits!