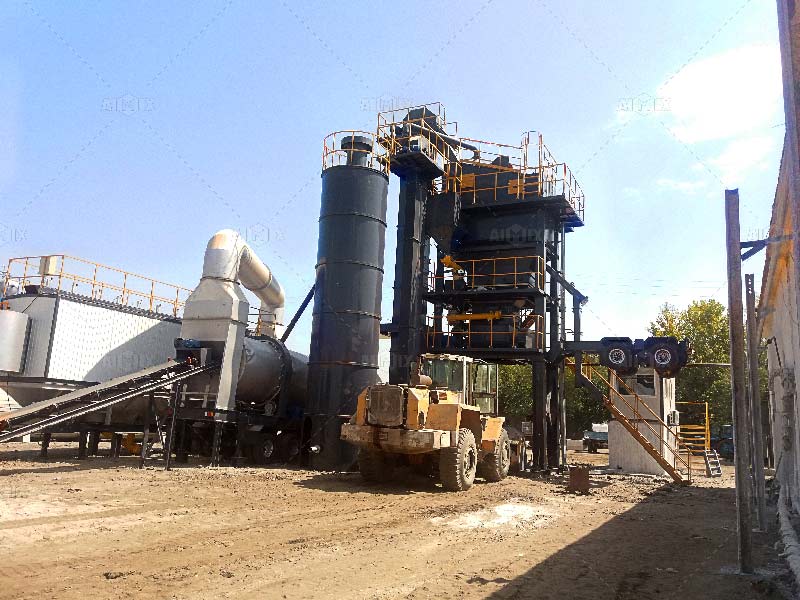

This series of products is equipped with advanced automatic monitoring and control systems to make the equipment more reliable. Its modular structure is designed in accordance with international transportation standards, safe and fast. It is more efficient and larger than continuous asphalt plants.

Models of AIMIX Discontinuous Asphalt Plant for Sale

At AIMIX, our discontinuous asphalt plants are divided into ALQ series of fixed plants, ALYQ series of mobile plants and ALYJ series of single plants. Below I will describe its features for you, respectively, you can get more information or contact us to get the latest price.

ALQ discontinuous fixed asphalt plant

2. The plant has precise and reliable systems for measuring and dosing aggregates, asphalt binders and other additives.

3. Compared with continuous asphalt plant, this type of asphalt plant is equipped with high efficiency mixer, which can produce higher quality asphalt mixture.

4. The factory has an advanced control system that can monitor and adjust various parameters so that the production process can be precisely controlled.

ALYQ mobile intermittent asphalt plant

2. Compared with fixed asphalt plant, it is more flexible to move and can be installed nearby according to the project location. The installation of mobile asphalt plant It is also more convenient, all components are placed on the trailer, and the installation can be completed in just 2 to 5 days.

3. This mobile batch asphalt plant is also equipped with high-precision weighing system and automatic control system, which can also guarantee the quality of production under the premise of being mobile.

ALYJ simple discontinuous asphalt plant

2. This single asphalt plant is also mobile and smaller in size, and is specially designed for mobile road construction projects.

3. It adopts small drying drum and double-shaft intermittent mixer, which not only ensures production quality, but also improves production efficiency.

4. This simple mobile asphalt plant has low initial investment and higher cost performance.

Technical Sheets for Discontinuous Asphalt Plants

ALQ fixed asphalt discontinuous plant

| Model | ALQ40 | ALQ60 | ALQ80 | ALQ100 | ALQ120 | ALQ160 | ALQ200 | ALQ240 | ALQ320 |

|---|---|---|---|---|---|---|---|---|---|

| Capacity | 40 t/h | 60 t/h | 80 t/h | 100 t/h | 120 t/h | 160 t/h | 200 t/h | 240 t/h | 320 t/h |

| Cold Aggregate Hoppers | 4×4.5m³ | 4×6.5m³ | 4×7.5m³ | 4×7.5m³ | 4×7.5m³ | 5×12m³ | 5×12m³ | 5×12m³ | 6×15m³ |

| Dryer Size | φ1.2m×5.2m | φ1.5m×6m | φ1.5m×6.7m | φ1.65m×7m | φ1.8m×8m | φ2.2m×9m | φ2.6m×9m | φ2.6m×9.5m | φ2.8m×10.2m |

| Fuel consumption | 70-300kg / h | 100-400kg / h | 120-600kg / h | 150-1000kg / h | 150-1000kg / h | 150-1400kg / h | 180-1800kg / h | 180-1800kg / h | 260-2500kg / h |

| Vibrating Screen (Layer) | 4 layers | 4 layers | 4 layers | 4 layers | 4 layers | 5 layers | 5 layers | 5 layers | 6 layers |

| Mixer Capacity | 500kg | 800kg | 1000kg | 1250kg | 1500kg | 2000kg | 2500kg | 3000kg | 4000kg |

| Cycle Time | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s |

| Filter Area | 230m² | 300m² | 420m² | 480m² | 550m² | 650m² | 700m² | 1050m² | 1350m² |

| Asphalt Temperature | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ |

| Total Power | 170kw | 200kw | 300kw | 350kw | 380kw | 490kw | 550kw | 670kw | 865kw |

ALYQ mobile asphalt batch plant

| Model | ALYQ60 | ALYQ80 | ALYQ100 | ALYQ120 | ALYQ160 | |

|---|---|---|---|---|---|---|

| Capacity | t / h | 60 | 80 | 100 | 120 | 160 |

| Mixer capacity | kg | 800 | 1200 | 1300 | 1700 | 2200 |

| Mixing cycle | s | 45 | 45 | 45 | 45 | 45 |

| Total power | Gasoline(kW) | 54 | 63.5 | 104.5 | 125 | 157.5 |

| Coal(kW) | 75 | 86.5 | 127.5 | 169 | 205 | |

| filter area | m2 | 370 | 420 | 480 | 510 | 620 |

ALYJ simple mobile asphalt plant

| Model | ALYJ10 | ALYJ15 | ALYJ20 | ALYJ30 | ALYJ40 | ALYJ60 | ALYJ80 | |

|---|---|---|---|---|---|---|---|---|

| Capacity | 10 t/h | 15 t/h | 20 t/h | 30 t/h | 40 t/h | 60 t/h | 80 t/h | |

| The ability to | Petrol | 48kw | 59kw | 68kw | 106kw | 132kw | 146kw | 186kw |

| Burning coal | 67kw | 78kw | 91kw | 129kw | 170kw | 192kw | 262kw | |

| Cold Aggregate Hoppers | 3m³×3 | 3m³×3 | 3m³×3 | 5m³×3 | 5m³×3 | 5m³×3 | 5m³×4 | |

| Finished Product Hopper | 2t | 5t | 5t | 9t | 9t | 9t | 20 t | |

| Asphalt Temperature | 120-180 ℃ | |||||||

| Fuel consumption | Petrol | 5-7.5kg/t | ||||||

| Burning coal | 13-15kg/t | |||||||

| Option | Water dust filter, Bag dust filter, Control room, Asphalt heat tank, Mineral flour tank | |||||||

How to Choose the Right Batch Asphalt Plant?

Asphalt is currently in high demand in the market due to its many uses, but for companies planning to venture into asphalt production, there are several factors to consider before deciding which asphalt plant comprar.

Project type and production requirements

The main criteria for deciding on a suitable batch asphalt plant are project planning and the long-term production requirements that the plant must meet. The type of project determines the production of different products, the quantity and quality of production, and even the location of the asphalt plant.

For example:

Stationary asphalt plants are usually suitable for scenarios that require high-quality and high-performance asphalt mixtures, such as the construction of urban highways and arterial roads, large bridges, tunnels, parking lots, etc., road construction in large industrial parks, etc. .

The mobile asphalt plant can adapt to the needs of various scenarios, such as temporary engineering projects, remote areas or mobile construction sites, urban construction and road reconstruction, as well as short-term and small-scale engineering projects.

Fixed or mobile

If the project is going to last several years, it would be ideal to choose a stationary asphalt mixing plant: transportation costs will be lower than mobilization costs. However, if the project requires moving the project site several times during the year, a mobile asphalt mixing plant is worth considering.

Asphalt plant scale

The size of the plant and equipment depends on the output that the company wants to achieve. As a good measure, a plant should have 80-90% productivity to be considered efficient.

Factory customization

The ability to customize asphalt equipment is another important criterion for selecting the right asphalt equipment. AIMIX provides personalized services for customers. Our engineers can formulate more suitable configurations according to customers' specific needs, so as to achieve better production results and save costs for customers.

Some common accessories that allow customization are: cooled aggregate silos, asphalt tanks, burners, finished product storage silos, dust collection systems.

After-sales support

Asphalt mixing plants are batch driven and continuous production. Even the smallest disruption to production can lead to project disruption and financial losses. Therefore, after-sales service provided by the manufacturer, ready availability of spare parts, qualified maintenance personnel and associated costs are important factors in keeping an asphalt plant running.

Why Buy AIMIX Discontinuous Asphalt Plant?

AIMIX batch asphalt plant is stable and is suitable for medium-sized companies. AIMIX can provide customers with the best purchasing plan. It has the capacity to satisfy all the needs of the asphalt plant with different functional accessories.

- 1. Quick transportation of equipment: All AIMIX equipment is modular in design. Each of its modules strictly meets the transportation requirements and is not very high or wide. Therefore, the demolition and transportation of discontinuous asphalt plant is as simple as the installation of the equipment. This can effectively improve construction efficiency and effectively guarantee the construction period requirements of the construction unit.

- 2. General compact equipment: Its dust removal system does not take up space. The powder supply system is very close to the main building. Therefore, the entire asphalt agglomerate plant has compact structure, saves space, has reasonable design and is convenient in installation.

- 3. Best overall design: Batch asphalt production plant has reasonable channel, cooling aggregate system and asphalt system can adapt to various site conditions.

- 4. Good product updating ability: The heat preservation system and additive interfaces are preserved, which is very convenient for product upgrading.

- 5. Tilted vibration screen: Thorough screening ensures a low mixing rate. And it is equipped with a dust-proof device with negative pressure leak prevention. In addition, it has a screen shell structure with thermal insulation design.

- 6. High environmental performance: With the latest technology and advanced equipment, the bitumen mixing plant It can reach the domestic advanced level in terms of gas emission and noise control. Plus, low power consumption can save a lot on your investment.

- 7. Lower unit weight of the asphalt plant: AIMIX always decreases the useless structures of plants by adhering to environmental protection. Therefore, AIMIX designs the lowest unit weight of a small asphalt mixing plant and saves more floor space.

Parts of Discontinuous Asphalt Plant

Dust removal system

Dosing system

drying system

Asphalt heating system

Weighing system

central control system

Contact Us

As the most representative batch asphalt plant manufacturer in China, our product and price can always satisfy you. Since we establish the cost of machines according to performance, brand parts and technology. And our product must work smoothly and bring you huge benefits. Furthermore, we will spare no effort to offer you the most attentive service.

Please feel free to send us inquiry and get more detailed information for asphalt plant. We will give you the best discontinuous asphalt plant!